Several alternatives are available when it comes to contracting and procurement methodologies for construction projects. One model often used in the energy industry is the EPC Contracting framework. But what exactly is it?

EPC Contracts are agreements in which the Contractor is responsible for the engineering (E), procurement (P), and construction (C) tasks of a project under a single contract. A significant level of risk transfer characterises these agreements, which are typically executed on a turn-key lumpsum basis.

In this article, we will further explore this contracting framework, understanding the pros and cons associated with it, as well as key features and its usability on construction projects.

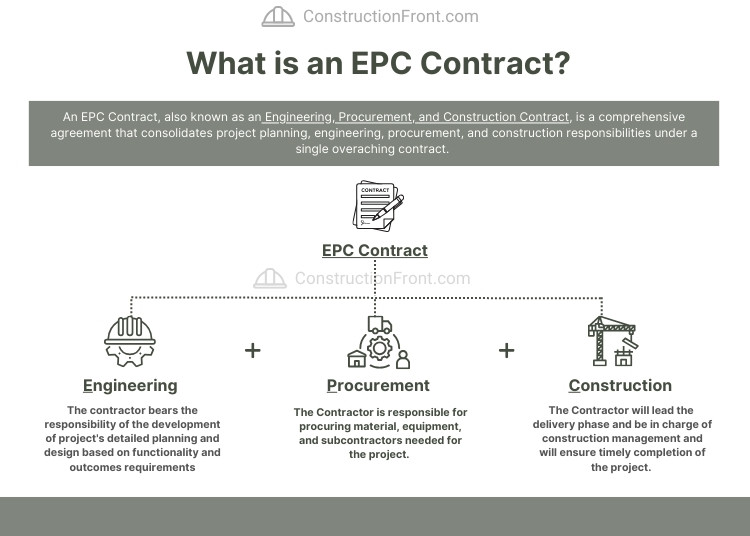

An EPC Contract, also known as an Engineering, Procurement, and Construction Contract, is a comprehensive agreement that consolidates project detailed engineering, procurement, and construction responsibilities under a single overarching contract.

Typically used for complex industrial projects, this contracting framework is commonly implemented by owners that have clear and specific outcomes and functionality/performance requirements for their projects but have not undertaken a detailed engineering yet.

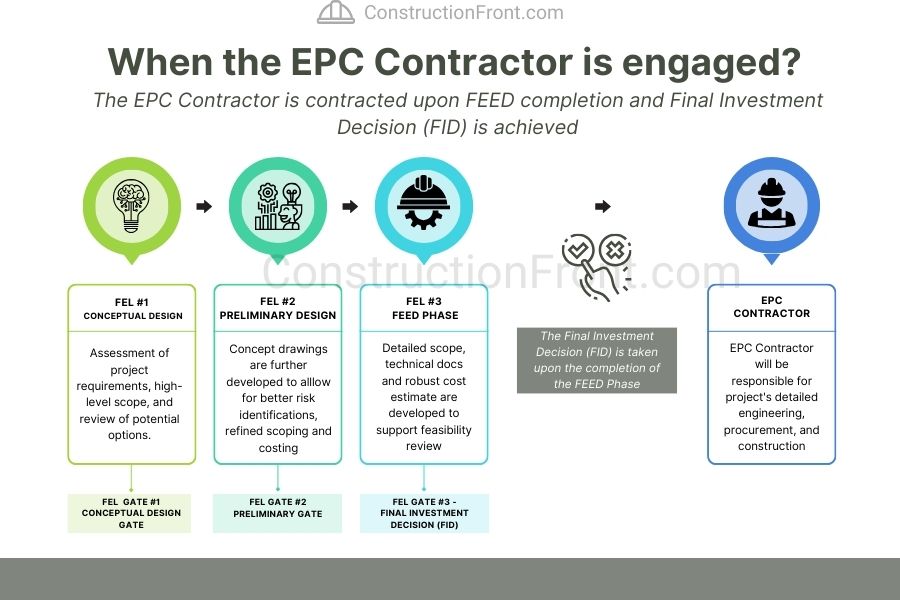

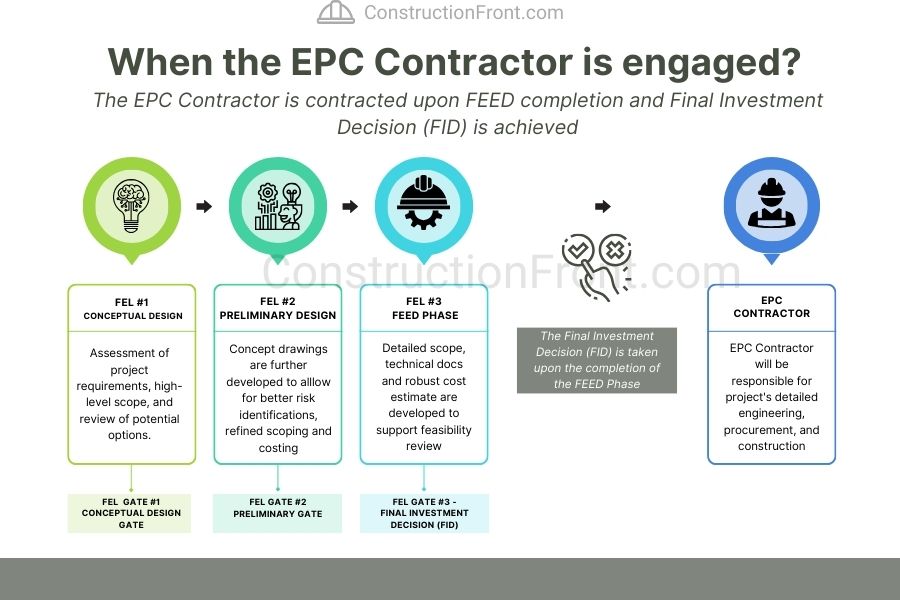

Commonly the EPC Contractor is hired once the project finalises the Front-End Engineering Desing (FEED) Phase and a Final Investment Decision is made by the Owner to proceed and build the new asset (see figure below)

Suggested Reading:

As the name states itself, in this contracting framework the contractor is typically responsible for the following activities:

EPC agreements are typically deployed when owners/investors wish to procure a project based on functionality requirements and specific outcomes rather than a set of specific designs and drawings.

From an owner’s perspective , the rationale is transferring risk to the EPC Contractor and leverage its expertise to develop and deliver projects . Therefore , owners should consider contractor’s previous experience and past performance in both the construction sub-niche (i.e. energy, transport, manufacturing plants, etc) and in this contracting framework, given the level of risk transfer and performance requirements.

Usually, these agreements are “turn-key” contracts, which means that once the project is finished, the a sset is fully operational and ready for immediate use without further adjustments or involvement from the client (the client only needs to “turn the key” to start operations).

Given the level of design detail when the EPC contractor is involved in the project, the agreements typically set specific performance requirements for the new asset instead of highly detailed drawings. The EPC contractor will then leverage its expertise to proceed with detailed engineering and find the most suitable solution from both technical and commercial perspectives.

Some common examples of project requirements are in the detailed table below by Nices – we have highlighted project requirements in bold to facilitate understanding.

Niche

Brief Description

Example of Project Requirements

Energy-related projects, particularly power generation, where functionality, performance, and safety are essential features.

Construction of a 1 00 MW wind farm.

Large-scale infrastructure projects like airports, metro lines, bridges, etc.

Building a major international airport for 10 million Passengers per year.

Factories and plants that require precise equipment installation and operational functionality.

Construction of a chemical plant that can process 100 ton of plastic per year .

Environmental and Remediation Projects

Environmental projects like wastewater treatment facilities.

Delivery of a wastewater treatment facility that can process a t least 10m3 of wastewater per hour .

With an investment of more than USD 3 Billion, Técnicas Reunidas and Sinopec Engineering Group were contracted by Saudi Aramco to develop new facilities to fractionate 510 thousand barrels per day (MBD) of Natural Gas Liquids (NGLs) in Saudi Arabia.

The project included two major EPC contracts detailed below:

Package

Description

Estimated Construction Duration

Riyas NGL Fractionation Trains (Package 1)

Consists of two trains, each processing 255 MBD. Incorporates fractionation, treatment, dehydration, and refrigeration units.

Riyas NGL Common Facilities (Package 2)

Common facilities include feed and product surge storage, chemicals storage, and utilities.

Utilities comprise steam and condensate recovery systems, utility water, plant and instrument air, nitrogen systems, machinery cooling water, drainage, and flare systems.

The UTE Pampa Sul is a 345MW coal-fired powered Thermoelectric Plant in Rio Grande do Sul, Brazil. Engie Brasil has contracted Shandong Electric Power Engineering Consulting Institute (SDEPCI) under an EPC Contract agreement to deliver the project.

Author’s Note : The author worked on this project between 2016 and 2017 supporting the contract and commercial activities for the EPC Contractor. The asset now is under Operation and has been sold by Engie Brasil in 2023 to investment funds Grafito and Perfin Space X.

According to this interesting article about EPC agreements, the EPC contracting strategy might vary slightly in accordance with client’s preference and market appetite.

The two models are commonly used:

In this approach, an EPC contractor will deliver the project, offering a fixed price for the entire scope . Usually, tenderers go through a competitive procurement process and offer a “lump-sum” amount to the specifications detailed by the owner.

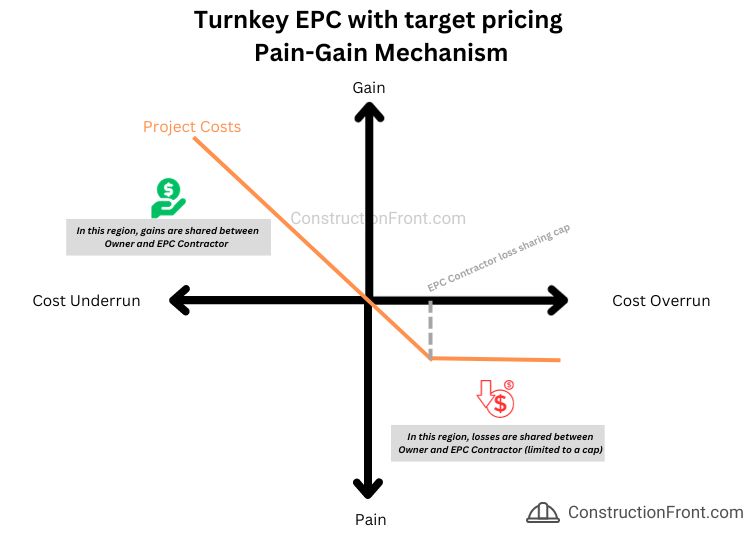

The EPC framework might also embed some level of risk-sharing mechanism between the contractor and owner in the contracting strategy. Similarly to the firm price approach, the contractor will go through a competitive procure process to deliver the entire scope of work.

However, instead of a fixed lump sum price tag, a target price is set, which usually contains a risk sharing mechanism (pain-gain), akin to the model used in alliance contracts.

In a nutshell, if the project is delivered below the target cost, parties share the gain; on the other hand, if there are cost overruns, owners and contractor share the losses (typically EPC Contractor’s exposure are limited to a loss sharing liability cap – refer to the picture below for further context)

Some of the key features of this contracting framework are detailed in the table below.

EPC – Key Features

Description

Outcome / Performance Based

EPC contracts are typically procured focusing on achieving specific project and performance and requirements.

Single Touch Point / Responsibility

A single entity (the EPC contractor or EPC JV Contractor) is responsible for all aspects of the project (engineering, procurement, and construction). This simplifies communication with the client/owner and almost extinguishes interface risks (for the owner)

Risk Transfer – Increased Cost, Program, and Scope Certainty for the owner

EPC contracts are usually procured on a turnkey lump sum basis, offering cost, program and scope certainty to the owner. There is a significant level of risk transfer from the owner to the EPC Contractor.

Use of Performance Guarantees

These contracts normally include performance guarantees of meeting performance and quality standards specified at the time of procurement.

It provides assurance that the project will be perform to the satisfaction client’s requirements. In case of non-compliance, the guarantor may be required to rectify the deficiencies or provide compensation as per the terms of the contract.

It can be a Parent Company Guarantee (PCG), Bank Bond (i.e. Performance Bond), and other alternatives available on the market.

Liquidated damages and Liability Caps

Given the level of risk transfer, EPC Contractors normally request liability caps to limit their exposure. Typical caps are:

• Usually capped at 100% of the Contract Price

• Sub-caps of 20% of the Contract Price on delay

(They might vary in accordance with jurisdictions, market appetite, and parties involved in the process).

Defect Liability

The defect liability period (DLP) to rectify construction defects usually varies from 12 to 24 months following achievement of practical completion.

Intellectual Property

Intellectual property with regards to technology developed for the project are typically held by the Owner, and the IP use by the EPC contractor without owner’s consent might trigger indemnities.

Force Majeure

Typically, the EPC contractor can be released from some of its obligations in case of force majeure events (wars, strike, riots, floods, etc.)

Termination

EPC Contractors have very limited termination rights, whereas owners usually have broader rights.